Earth Anchors Or Disposable Stakes

This type of snare or trap anchoring system is certainly not a new idea north American trappers have been using them since the early 1940’s. The disposable stake or earth anchor as they are called are very economical and light in weight and easy to carry, a hundred can be carried in your bag with relative ease. Like any product that is devised, over the years of being used on a regular basis new and more modern up to date additions start to develop. E.g. Ron Hansen came up with the Iowa disposable stake, Slim Pederson modified it with a simple steel plug inserted into one end, this stopped soil clogging the driver and the earth anchor together, now we have flat steel anchors of different shapes and sizes, the simple mudguard washer makes another good earth anchor.

The Americans have developed the bullet earth anchor an all in one moulded piece of cold rolled steel which is also an excellent anchor. All of the latter types of anchor have steel cable attached to them, a valuable commodity that should really be used making snares. In 1987 I came up with an idea that eliminated the use of wire snare cable, and started to use high tensile galvanised fence line wire, the English Tinsley wire is the best as the foreign imports are not as strong and springy, the galvanised coating also flakes off at times. I incorporated a spring handle on the wire at the opposite end from the anchor, this simple addition eliminated all other devices of attachment, because you just squeezed the handle to open, then attach your snare swivel and squeeze to close, setting snares became a two minute job. I use 3mm high tensile wire which is very strong, my peter who is a pro trapper out in north western Canada uses these type of earth anchors to hold coyotes between 40 – 50lbs. Some of my friends use them throughout the UK, Australia and New Zealand.

In the following illustrations I have drawn, you will be able to follow clearly and make your own earth anchor for a few pennies instead of paying anyone for them. Some of the items used can be picked up for free or for pennies, such as wall ties, and washers, the Saturday markets are ideal also car boot sales or from friends who work with them every day in the trade. I hope this information along with the illustrations I have drawn helps outdoor men to become more self proficient in making their own equipment for practically nothing, as the cost of commercial products are for ever rising.

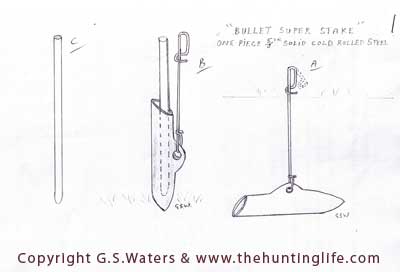

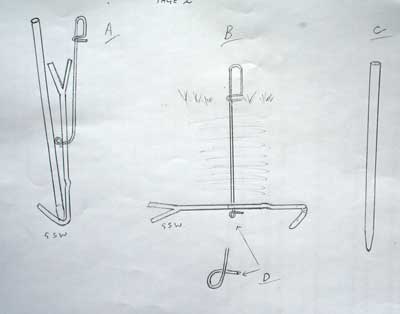

Bullet Super Stake

One Piece 5/8" Solid Cold Rolled Steel

A. This anchor is all in one moulded unit very good for hard ground. Once again the high tensile wire works good with this anchor and eliminates the use of snare cable.

B. READY TO INSERT STAKE INTO THE GROUND

C. STRAIGHT BAR DRIVER

These stakes are sold in USA.

*Click To Enlarge

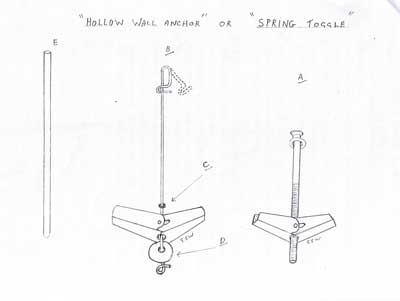

Spring Toggle Anchor

G.S.W Style

*Click To Enlarge

A. Spring toggle used in construction

B. Remove Bolt, add a length of high tensile 3mm wire as seen with formed spring handle.

C. Add a small steel nut and set permanently just above toggle this keeps toggle from sliding up wire, when it is being pushed down into hole. (do this operation last).

D. Add a good thick ¾” washer this gives toggle added strength when set underground in open position, to hold everything in place just loop wire around on itself as seen.

E. Straight driver bar to make hole in ground then push toggle down into bottom of hole and pull to set in open position. Nut stops toggle sliding up wire, my method eliminates hollow copper pipe which is needed to push toggle into hole if wire cable is used on anchor. My idea of using high tensile wire with the spring handle on all anchors eliminates the use of valuable snare cable and also any other devices such as clips or hooks etc. To secure your snare swivels or trap rings , its so simple squeeze handle to open then attach snare or trap chain and squeeze to close , it’s a two second job and cheap to make.

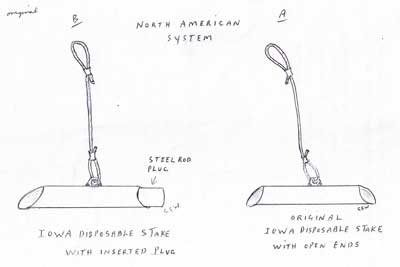

Iowa Disposable Stake

*Click To Enlarge

A. This stake was devised by Ron Hansen, a coyote trapper in USA many years ago and was later used in the UK.

B. Slim Pederson another good trapper from montana added a steel plug at one end, this idea eliminated any soil getting into the pipe and jamming the driver and anchor together, good for hard ground.

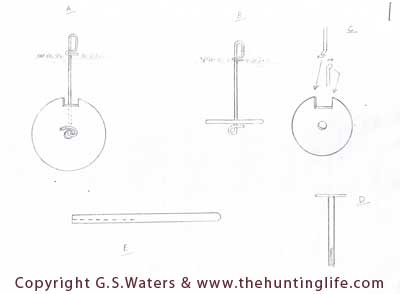

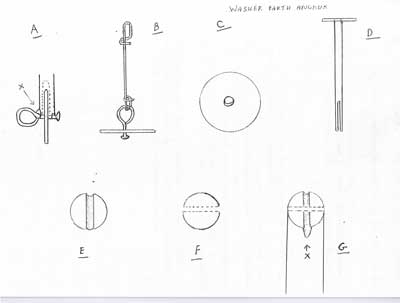

Washer Earth Anchors

G.S.Waters Washer Anchor Style "Devised 1987"

*Click to enlarge

A. Washer with small slot cut out and high tensile wire showing spring handle and wire turned into loop at bottom to hold unit together.

B. Anchor set in ground, with only spring jandle showing for quick two second attachment of snare swivel.

C. Showing slotted mudguard washer with corners offset to keep washer stable on driver.

D. T Bar Handle

E. 8 inch length 3/8" steel bar with 4mm hole drilled up the centre make a good wire bender,

This method is as simple as you can get and the device was made for pennies, but a few year ago a method called the pogo stick method arrived and it is a very good method.

Washer Anchor

*Click to enlarge

A. Showing washer held in driver ready to be inserted into the ground.

B. Anchor in set position using high tensile wire.

C. Mudguard washers can be used 1 1/2" and 2" diameter the 1 1/2" washer holds coyotes and a 2" washer holds a wolf.

D. T Bar Driver

E. Shows the plan elevation or bottom view of driver bar with a 5mm groove cut across end face of bar.

F. Shows a 1 1/2" deep slot cut across end face of driver bar.

G. Shows the finished device the groove runs from top to bottom and the slot runs from side to side as seen.

X. Bar shows a groove filed at a 45deg angle, this groove correlates with the angle of the J hook at illustration point (A) this is how J hook must face at point of ground insertion.

This method can be purchased along with top quality driver bars already grooved and slotted from USA makers, its a very simple and effective method.

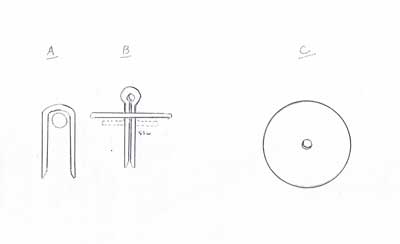

Washer Anchor

*Click to enlarge

A. Shows a large fence staple with a nail sitting within the unit.

B. Shows staple after the legs have been compressed together in a vice, the nail maintains an eye hole, insert staple through washer hole and bend legs back as shown then snip off excess, always leave space on either side of washer so that the driver bar can fit onto J hook, nail or staple.

C. 2" washer, make sure that when you purchase washer that the centre hole diameter suits your needs, holes can be drilled out to a larger diameter if needed.

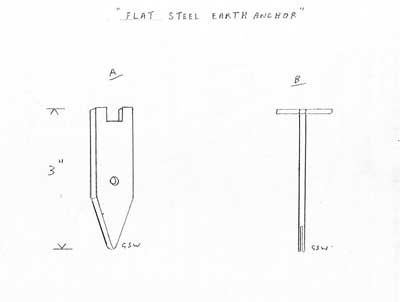

Flat Earth Anchors

Used In Soft To Medium Ground

*Click to enlarge

Flat Steel Earth Anchor

A. Cut flat steel bar as seen, shape and drill, good in harder tyoe ground.

B. Driver Bar

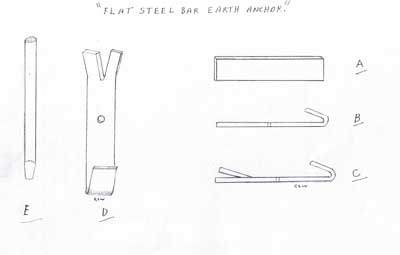

Flat Steel Bar Earth Anchor

*Click to enlarge

A. 4 1/2" length of flat steel bar.

B. 3/4" Bend as seen.

C. Once a few have been completed drill holes in middle then hold in vice and cut 3/4" down from end with a grinder, then offset the forks.

D. Completed Anchor

E. Driver Bar

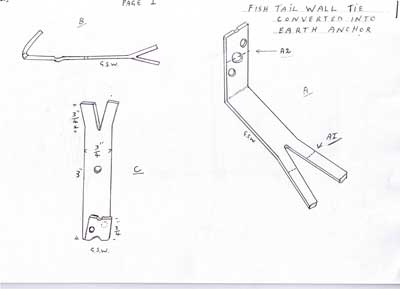

Fish Tail Wall Tie Earth Anchor

Devised By G.S.Waters (For Softer Type Ground)

*Click to enlarge

A. Put wall tie into vice and straighten out then hammer flat.

B. Put in vice and bend end as seen at (A2) cut forked tail off at (A1) leave remaining forks 3/4" long, after you have made a few drill holes in middle.

C. How finished article looks.

*Clcik to enlarge.

A. Anchor in position, Ready to be hammered into ground.

B. Anchor is set in position underground, spring handle above ground.

C. Driver bar.

D. Shows how to loop high tensile wire around on itself this is a very simple and effective method, and will never pull off.

All illustrations copyright G.S.Waters | www.thehuntinglife.com